PROJECTS

Palletizing island for cardboard boxes

The robotic island was designed to automate the palletizing and wrapping process of cardboard boxes of different sizes.

This automation is made up of several elements, including a custom-made motorized conveyor complete with high-friction belt, a vertical elevator and descender, a connecting overhead conveyor, a metal detector to detect foreign bodies, an anthropomorphic robot, a gripper and finally pliers and winders.

PROJECT NEEDS AND SPECIFICATIONS

- Eliminate manual and repetitive effort for the operator

- Versatility of the system with different formats and sizes of cardboard boxes

- Carry out a complete cycle, from palletising to wrapping

- Integration within an existing system

- Automatic pallet collection at the end of the cycle

- Carry out automation in narrow spaces.

- Creating a buffer for the cardboard boxes so that there was no downtime;

PERFORMED ACTIVITIES

- Feasibility Study

- Concept and project

- HW and SW design

- Mechanical design

- Switchboards and wiring

- Test and Installation

GOALS ACHIEVED

- Considerable increase in production

- Operator relieved of a considerable physical load

- CE certification of the product

- Perfect integration with the automations already present in that area

- Freedom to increase and decrease the speed depending on the product to be palletised

- Freedom to calibrate and calibrate the heights of the robot based on the type of cardboard

PROJECT RENDERING

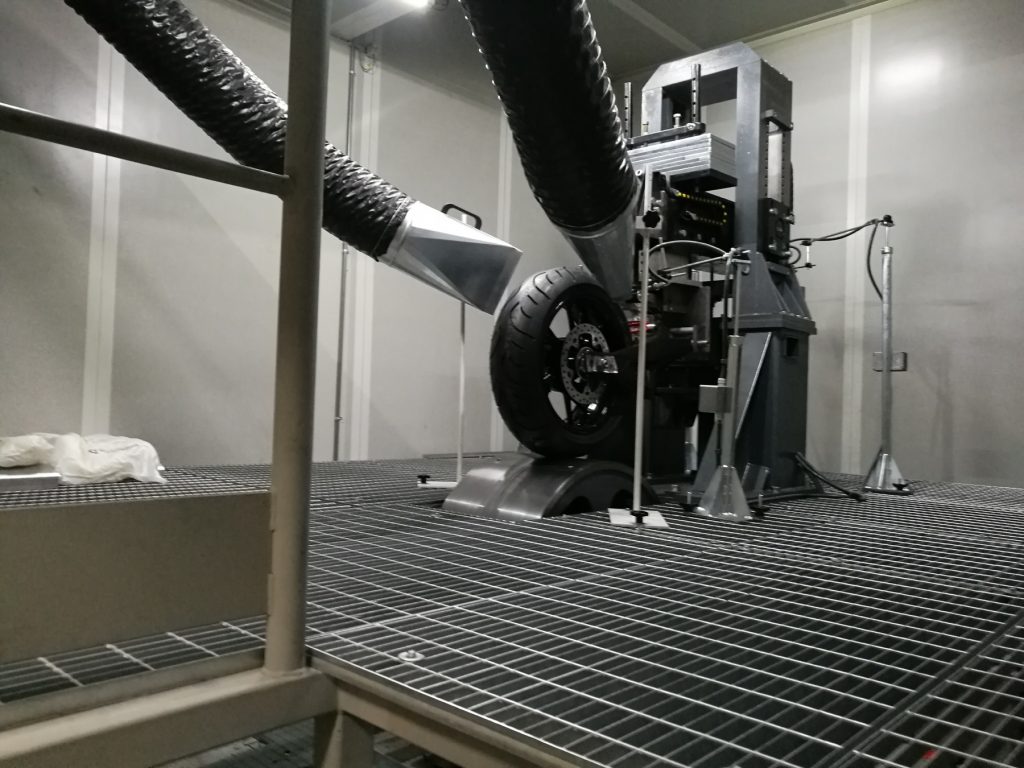

GALLERY

YOU MAY ALSO BE INTERESTED IN: