The history of AEPI Group

more than 50 years of progress

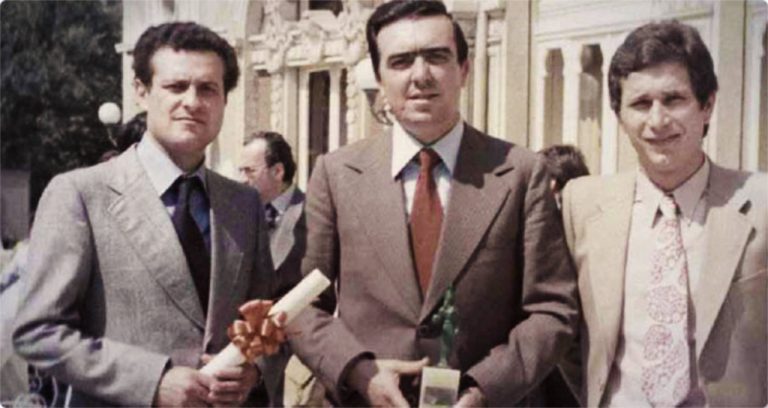

1969

AEPI Automatismi Elettrici Pneumatici Imolesi was founded in 1969 from the idea of three young entrepreneurs, including Tonino Topi, progenitor of the Topi family and current owner of the Group.

We were founded as a partner in the design and optimization of electrical and pneumatic systems for any industrial technological processes, and manufacturer of transformers and static machines.

1970

The 1st production plant of AEPI was established, which today continues to be an operating unit hosting the engineering department of the Group, named IPREL Progetti.

1979

10 years in business

1988

Following the first collaborations and the expansion of production, the first logistical problems began to arise.

We decided to move the production site to what is still the largest plant of the Group, therefore expanding both in terms of production and personnel.

We also witnessed the first company transformation: from AEPI Automatismi Elettrici Pneumatici Imolesi to AEPI Costruzioni Elettromeccaniche Srl.

1989

20 years in business

1995

IPREL Imola PRogetti ELettrici was founded in 1995 by a joint venture between AEPI Industrie and its historic partner Sacmi Imola. IPREL assumed a key role within the AEPI Group, further broadening the range of engineering services offered.

1999

30 years in business

2001

International directives were introduced in terms of product and safety (UL, CSA, Atex), representing a valuable element to cope with internationalisation: it became strategic for any manufacturer of machineries and equipments, relying on a partner with the expertise and experience necessary to ensure that everything was carefully taken care of.

2004

The evolution continued with the integration of NOVANET Ingegneria e Sistemi, a company based in Lugo that deals with the programming and integration of engineering systems in the field of management and automation of buildings, as well as in home and building automation.

2006

The three companies of the Group become part of the Tli Consortium, active in the supply of high-tech systems and services for logistics, integration between processes and management/decision-making information systems of companies.

2009

40 years in business

2010

The third production plant of the Group was established, which now hosts the head office and production site

2011

The expansion of the Group continued with the acquisition of El.Mecc., a company with proven experience in the field of electrical switchboards for industrial automation, energy distribution and Low or Medium voltage substations, and ECR ElettroCablaggiRomagnola, specialised in crimping, application of pin terminals, labelling of wires and cables for wiring.

2012

We witnessed the company’s transformation from NOVANET Ingegneria e Sistemi to NOVANET Impianti e Sistemi. At the same time, a structural transformation started with the incorporation of El. Mecc. Srl Costruzioni e Assemblaggi Elettromeccanici and E.C.R ElettroCablaggi Romagnola Srl, whose core business concerns the design, supply and marketing of electrical switchboards, therefore allowing and providing complete services.

Again in 2012 AEPI Costruzioni Elettromeccaniche took on a new corporate role becoming AEPI Industrie, keeping intact the brand and the global leadership in the fields of industrial automation and system integration.

2015

20 years in business of IPREL Progetti

2017

NOVANET Impianti e Sistemi is totally incorporated into the AEPI Group, with the consequent transfer of the personnel to the Group’s current production site.

2018

A new Business Unit was established within the Group, called AEPI Special Division and is dedicated to the design and optimization of tailor-made automatic machines for industrial automation for every production sector.

2019

50 years in business

2020

Transfer of the entire IPREL Progetti shares to our partner and long-standing customer: SACMI Imola Sc.

PROJECTS

Ad hoc technological solutions

Gruppo AEPI è particolarmente competitivo nella realizzazione di progetti personalizzati.

L’elevata flessibilità progettuale consente di raggiungere standard elevati in termini di affidabilità e qualità del prodotto finale.